http://www.visicadcam.com/

Part Unfolding | VISI 2020.1

The new unfolding technology provides the ability to work directly on the original solid model and support blanking functionality and management of parts with non linear bends. It allows to combine linear blank unfolding and flange unfolding, into a single combined functionality. Another major advantage is the associativity provided with the original model during the Die design process as this allows the original part to be modified and changes to be automatically propagated on the blanked part. This version also provides a direct interface from VISI to the Stampack Xpress product, for Die simulation purposes.

http://www.visicadcam.com/

Reverse | VISI 2020.1

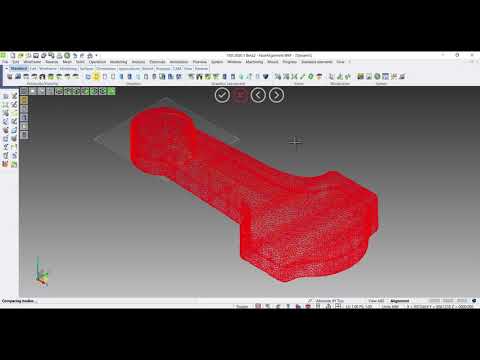

New features have been added to support the scanning to surfaces generation. Features such as radius generation from mesh, plane generation, adapt mesh on boundary, sectional curves on mesh provides greater benefit for the reverse process from point scanning to surface and solid model generation. The enhancements achieved provide quality improvements as well as time saving for the reverse process.

http://www.visicadcam.com/

Casting | VISI 2020.1

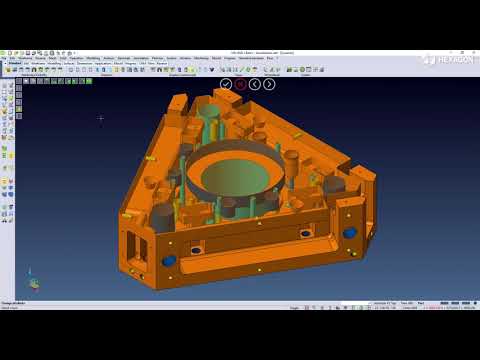

New Best fit feature allows the user to align a stock model to the final solid model by setting tolerances on different faces. This is extremely useful for the casting market as it allows to scan the cast model and achieve a best fit alignment with the final geometry in order to produce an optimised toolpath and reduce the machining time for manufacturing. The stock model can also be used for machining simulation purposes. The Compare feature provides an enhanced graphical evaluation of the results and to display distances between the scanned model and the final solid model.

http://www.visicadcam.com/

Body to Mould | VISI 2020.1

New body to mould functionality has been introduced which provides a quick solution to define the correct position and orientation of a plastic part on the tool. The feature allows to achieve the transformation of the model from the “car in line” position to the mould position and to apply the required shrinkage value. This is extremely useful especially, but not only, for the automotive market as it provides a time saving for the mould design process.

http://www.visicadcam.com/

Deburring | VISI 2020.1

The new Deburring strategy provides an automatic finishing of the sharp edges of the machined part, an important phase on the manufacturing process for all those parts that have not tangent surfaces. Deburring creates a tool path to deburr sharp edge of a workpiece with a spherical tool highly automated. Afterwards is automatic tilting and linking is applied to avoid collisions. This machining strategy reduces the setup time of deburring operation significantly due to is highly automated design.

http://www.visicadcam.com/

Autotilting | VISI 2020.1

The Autotilting technology on the 5 Axis has been enhanced on this version with new smoothing options, aimed to optimize the contour while keeping the tilt angles in a limited range. The result of this is a more fluent movement of the machine while milling the part.

http://www.visicadcam.com/

Enhanced Graphics | VISI 2020.1

New graphical representations have been delivered with this version to support the designer on the validation of the model for manufacturing purposes. The Undercut and Accessibility shading provides the ability to identify undercut areas of a model also during the design and modelling phases. The advantage provided is the ability to validate a model for manufacturing purposes at an early stage in the design to manufacturing process.

http://www.visicadcam.com/